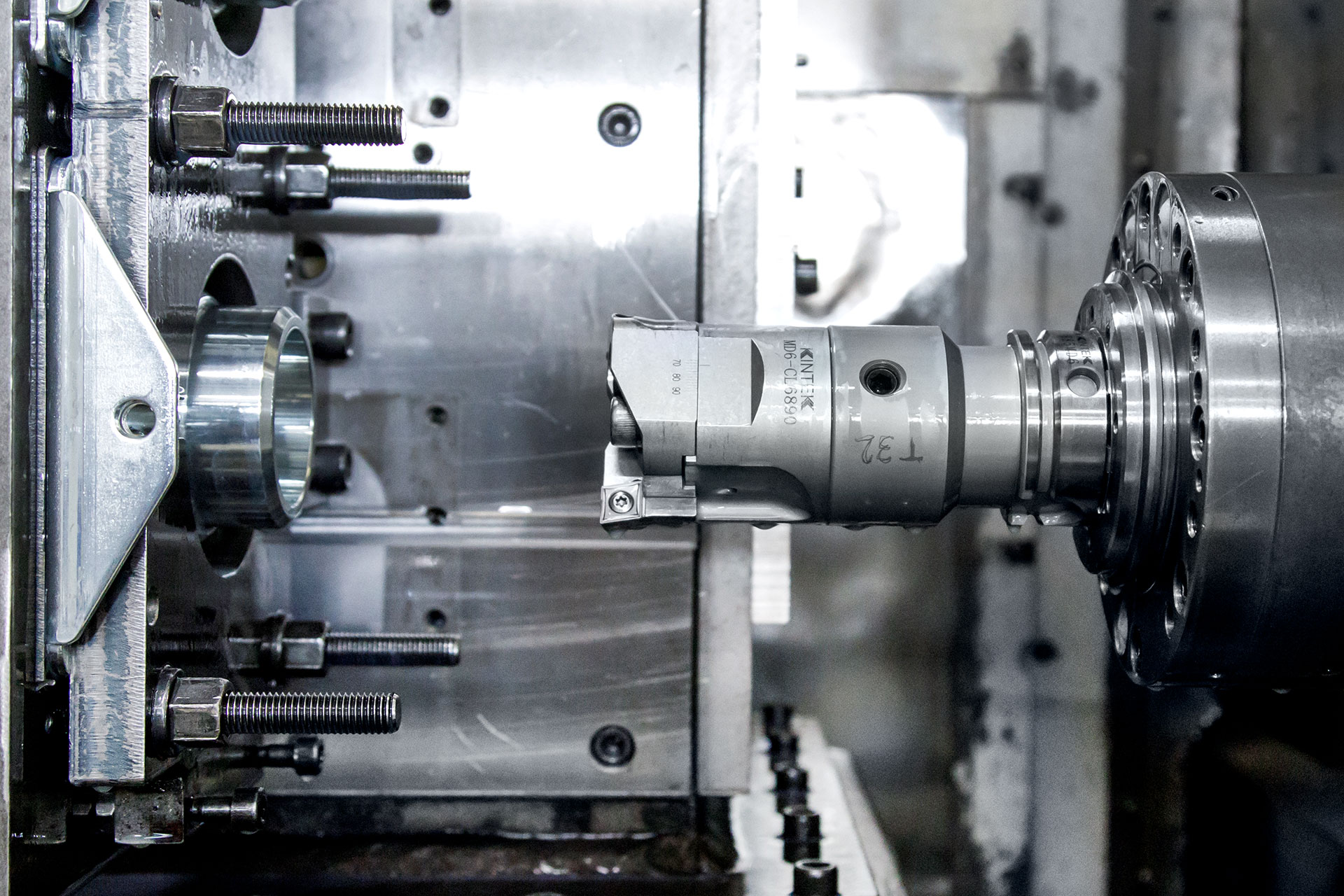

Machining sector

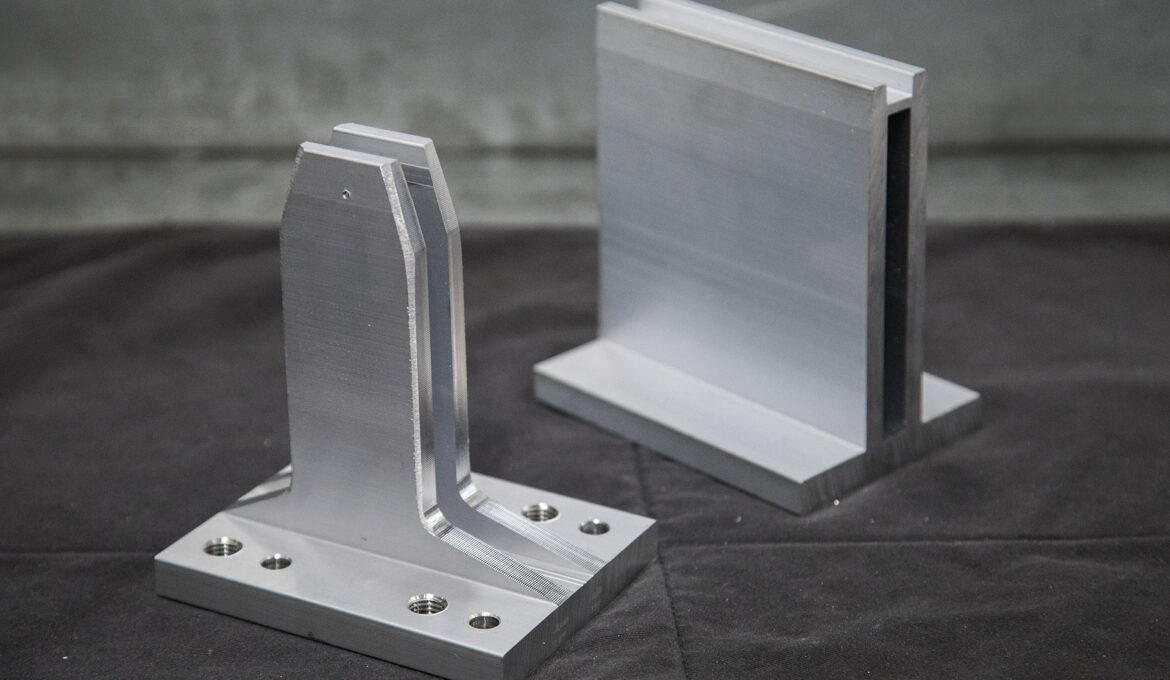

Materials processed: structural steel, quenched and tempered steel, stainless steel, aluminum, brass, and cast iron.

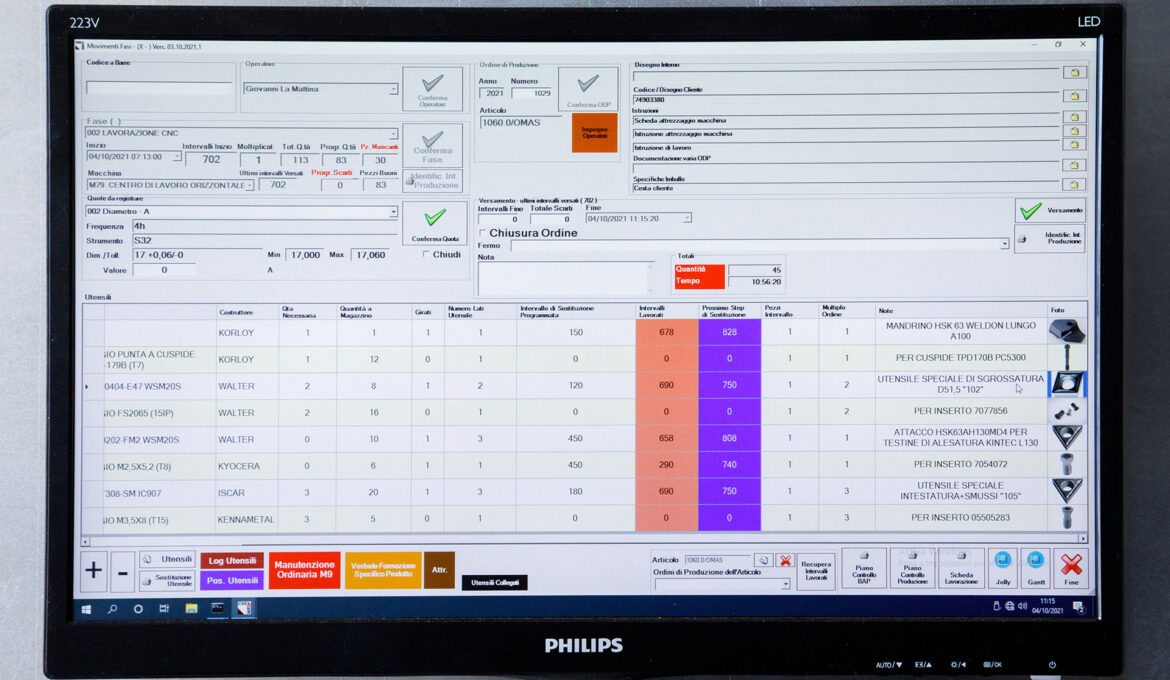

We design and manufacture in-house all the tooling required for production.

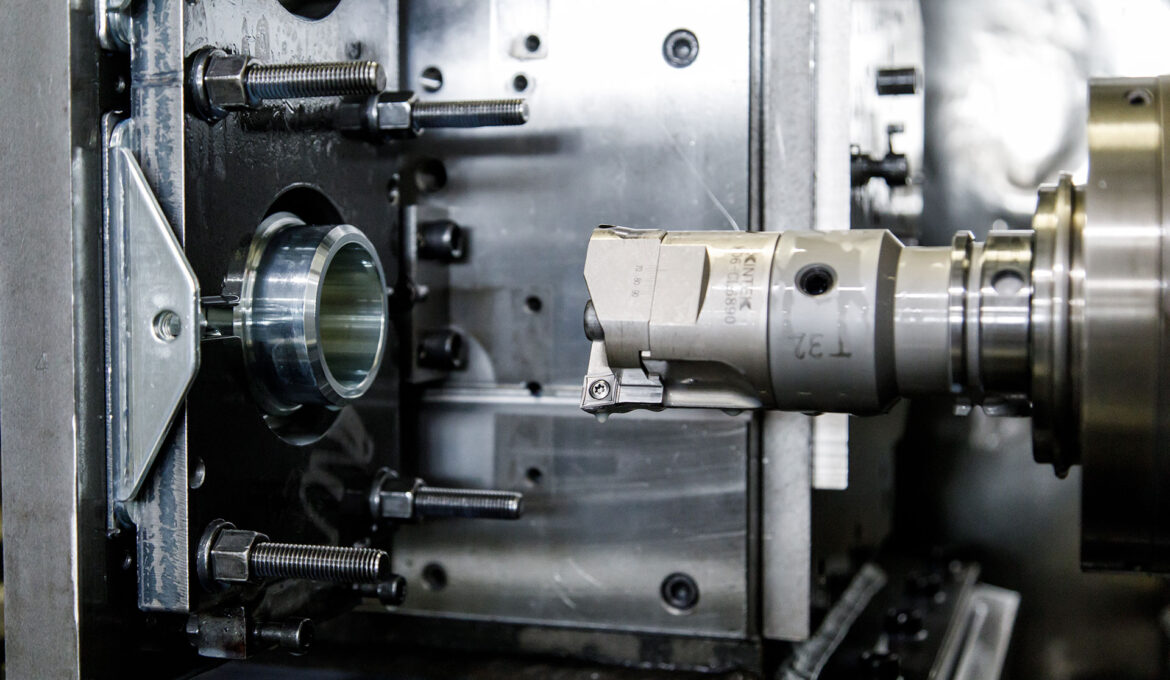

Chip removal

Metal cutting

Band saw cutting with CNC machines for all types of metallic materials

Disc cutting for light alloys

Mechanical Machining

Customization according to customer requirements.

Stamping

Machine Park

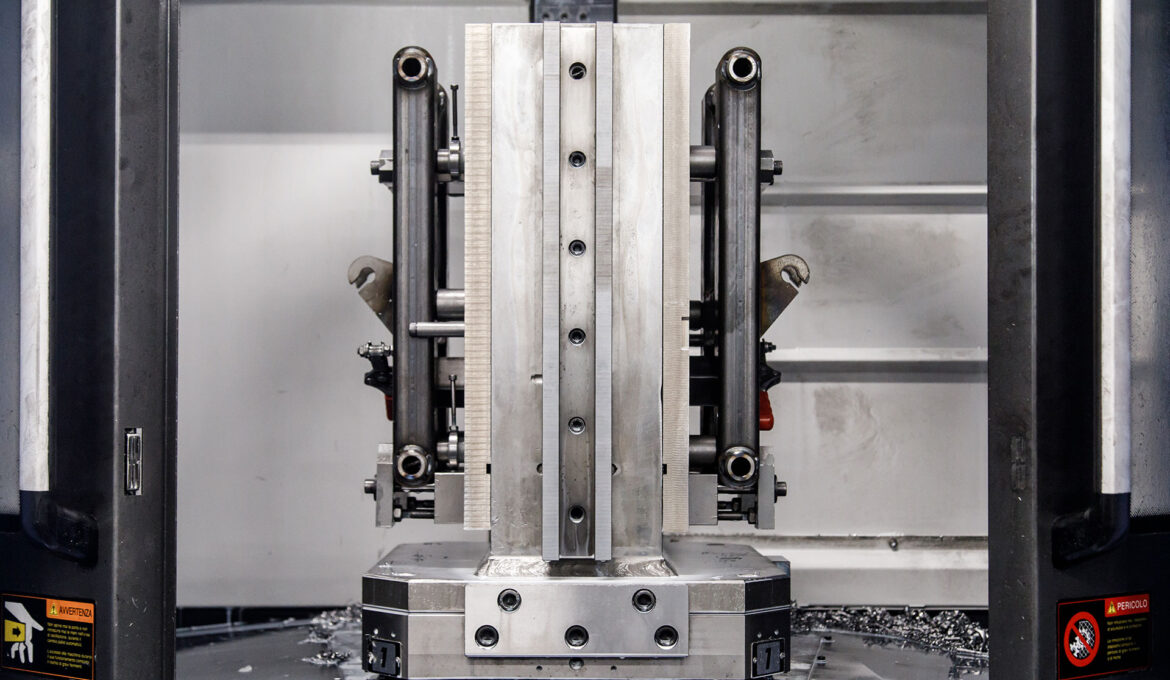

• 3 Horizontal machining centers with pallet changer, DOOSAN HC 500 – Travel 850*700*750 mm – 8000 rpm

• 1 Horizontal machining center with 10-pallet magazine, HELLER MCi 25.2 – Travel 800*800*800 mm – 10,000 rpm

• 1 Horizontal machining center with 6-pallet carousel, HELLER MCi 25.2 – Travel 800*800*800 mm – 10,000 rpm

• 1 Vertical machining center, Awea 850-BM – Travel 800*600*600 mm – 8000 rpm

• No. 1 DOOSAN LYNX2100 LSYA LATHE X-axis travel: 205 mm – Y-axis travel: 105 mm – Z-axis travel: 560 mm Maximum bar turning diameter: 51 mm Maximum secondary turning diameter: 300 mm Maximum turning length: 510 mm Main spindle: 6000 rpm Sub spindle: 6000 rpm Driven tools: 6000 rpm 24 tools

• No. 2 DOOSAN LYNX2600SY LATHES X-axis travel: 250 mm – Y-axis travel: 105 mm – Z-axis travel: 680 mm Maximum bar turning diameter: 81 mm Maximum turning diameter: 300 mm Maximum turning length: 610 mm Main spindle: 3500 rpm Sub spindle: 4500 rpm Driven tools: 6000 rpm 24 tools